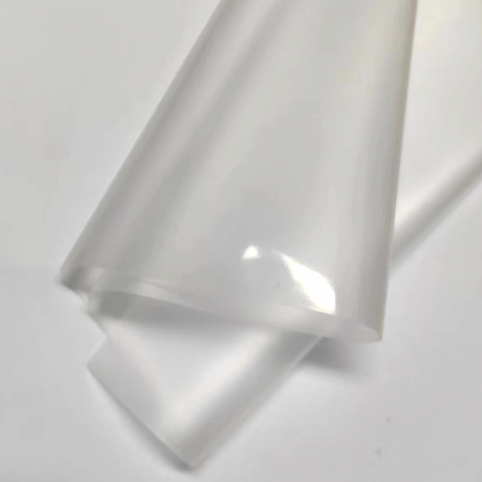

TL-LUPU-2509 Premium PU Leather for Style and Durability

Production Specifications

|

Material |

PU leather |

|

Material Composition |

45% PU, 55% Polyester |

|

Width |

54 inches |

|

Color &Texture |

various texture available, can be customized |

|

Appearance: |

Smooth, glossy appearance with a texture resembling real leather |

|

Finish: |

High release - allows for easy removal from mold |

|

Durability: |

Resilient and long-lasting material; can resist scratches, wear, and tear |

|

Water Resistance |

Water-resistant material; easy to clean and maintain |

|

Advantage |

15-20 days delivery time, pairs of service, quality control from the source |

|

Breathability |

Less breathable than genuine leather; may retain heat and moisture |

|

Eco-Friendliness |

Synthetic material alternative to genuine leather; environmentally-friendly and cruelty-free |

|

Usage |

sofa,car seat,bag,upholstery,shoe,floor,Furniture,Garment, Notebook,etc. |

|

Cost |

Less expensive than genuine leather; cost-effective alternative |

Standard Physical Properties

● Yellowing discoloring after @70℃≥ 4.0 grade

● Color change after hydrolysis ≥ 4.0 grade

● (Temperature 70°C, Humidity 90%, 72 Hours)

● Bally flexing dry : 100,000 Cycles

● Tear growth strength ≥50N

● Peeling strength ≥ 2.5KG/CM

● Color fastness to crocking ≥ 4.0 grade

● Taber H22/500G)

● Taber abrasion>200 Cycles

● Chemical resistance passed REACH, ROHS, California 65 and RSL tests of various brands

Advantages of High Elastic PU Material

Section 1: Introduction

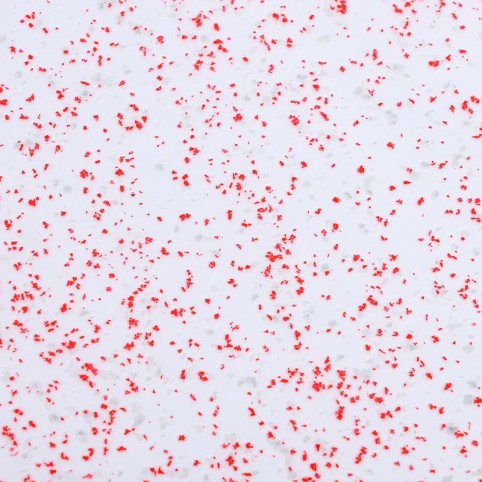

Reflective glitter effect foaming PU leather is a high-quality synthetic material with a unique glitter and reflective effect. It is a top-notch material for the production of luxury fashion items, upholstery, and other high-end products that require a glamorous look and high performance.

Section 2: Features and advantages

Section 1: Introduction and Overview

Dry production PU leather is a high-quality, synthetic material that is designed to replicate the appearance and texture of genuine leather. It is manufactured using a unique, dry production process that involves coating natural or synthetic fibers with a polyurethane layer. This creates a smooth and glossy surface that is highly durable, water-resistant, and easy to maintain. PU leather is an excellent, cost-effective alternative to genuine leather that is environmentally-friendly and cruelty-free.

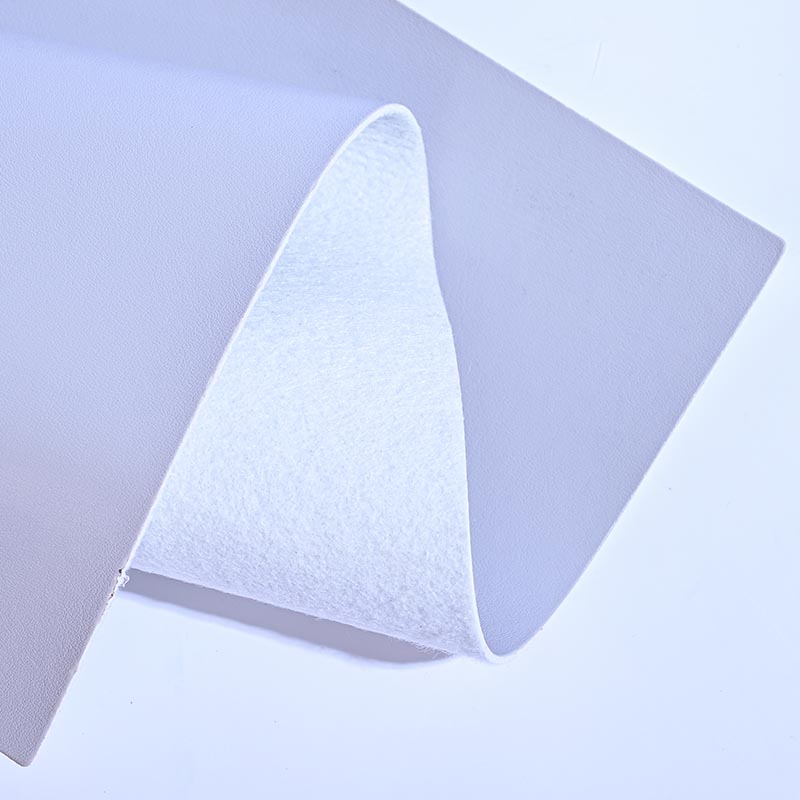

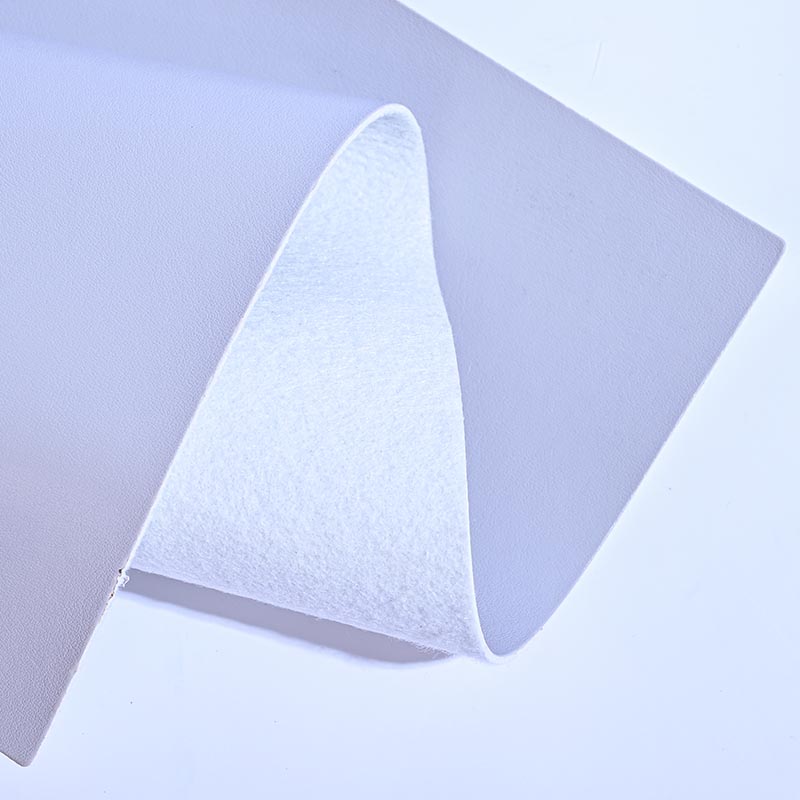

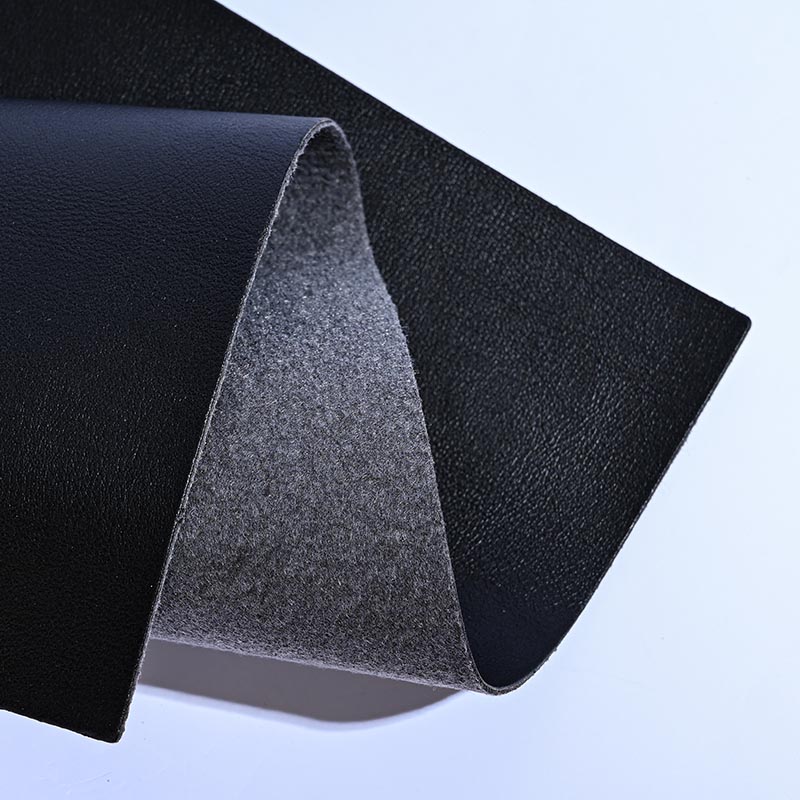

Section 2: Material Composition

Dry production PU leather consists of a layer of polyurethane that is bonded to a fabric base. It is made using a dry production process, which means that there is no chemical residue or waste. The production process ensures that the material is uniform in texture and thickness, making it ideal for use in a variety of applications.

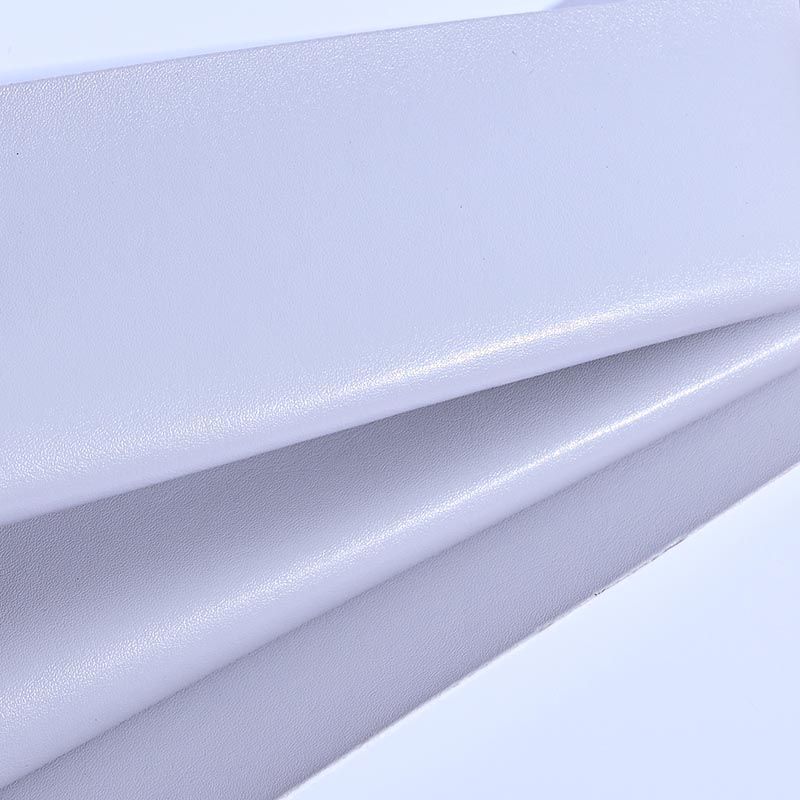

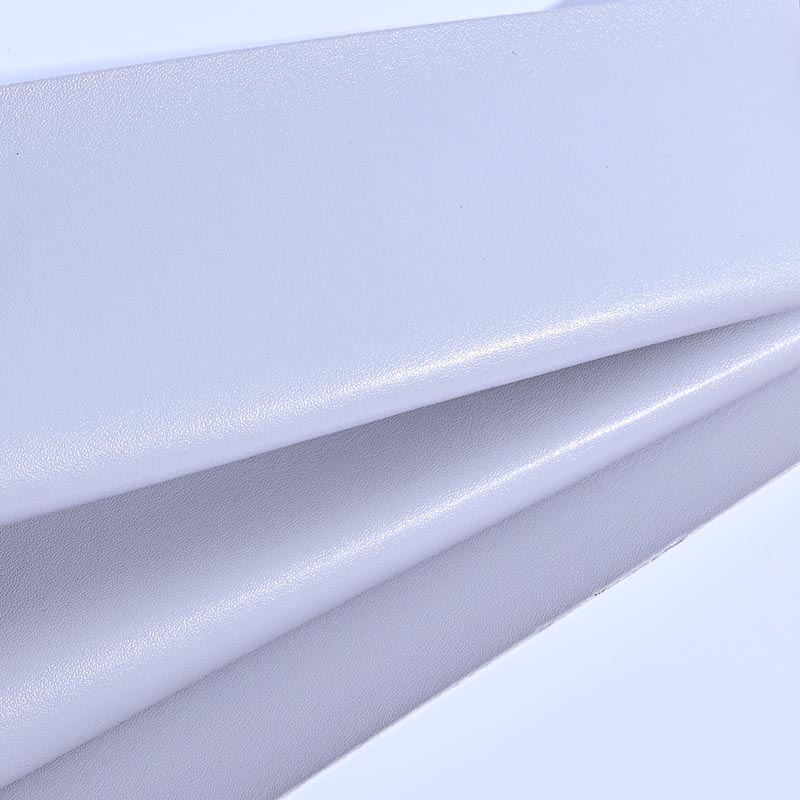

Section 3: Appearance and Texture

The appearance and texture of dry production PU leather is similar to that of genuine leather. It has a glossy, smooth surface that is soft and supple to the touch. The material is available in a range of colors, textures and patterns that mimic the look of real leather.

Section 4: Durability and Maintenance

Dry production PU leather is highly durable and resistant to scratches, wear, and tear. It is also water-resistant, making it easy to clean and maintain. The material is suitable for use in a wide range of applications, including clothing, shoes, furniture, and automotive upholstery.

Section 5: Benefits

Dry production PU leather offers a number of benefits over genuine leather. Firstly, it is more affordable, making it an excellent choice for those on a budget. It is also eco-friendly, as it is a synthetic material that does not require animal hides. Additionally, it is easy to care for and maintain, and is suitable for use in a variety of weather conditions. Finally, it is a highly versatile material that can be used in a variety of applications, making it an excellent choice for designers and manufacturers.