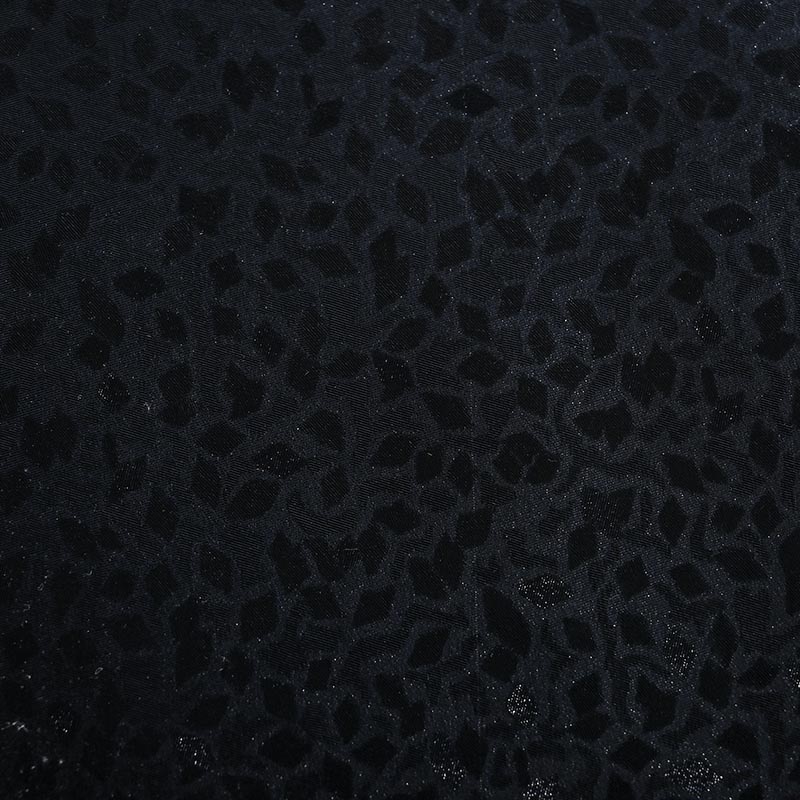

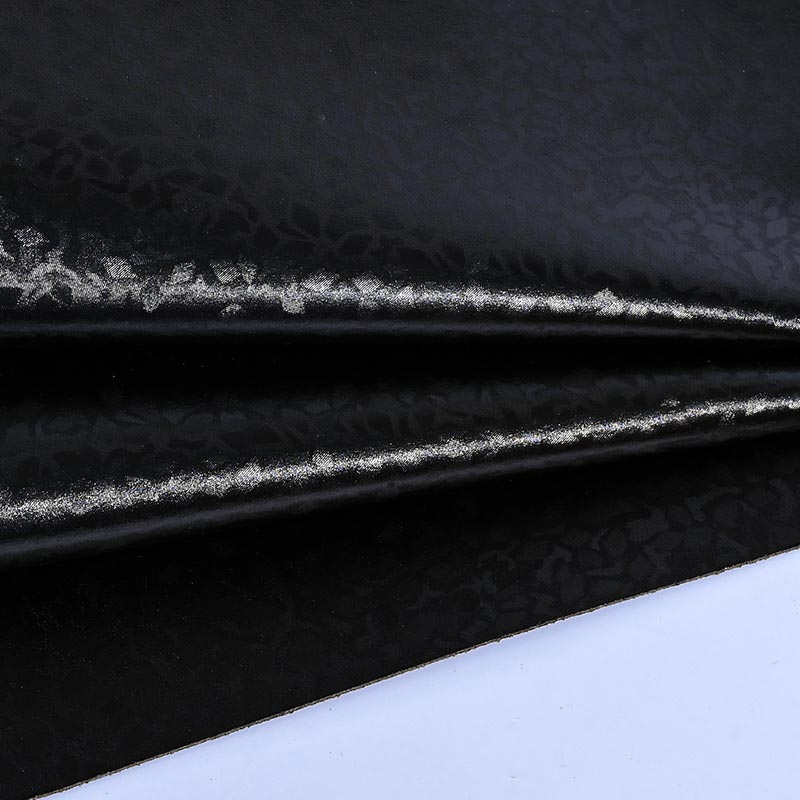

TLMF-102 Versatile Microfiber Leather for All Applications

Production Specifications

|

Material |

Microfiber leather |

|

Material Composition |

45% PU, 55% Polyester |

|

Width |

54 inches |

|

Color &Texture |

various texture available, can be customized |

|

Appearance: |

Smooth, glossy appearance with a texture resembling real leather |

|

Finish: |

High release - allows for easy removal from mold |

|

Durability: |

Resilient and long-lasting material; can resist scratches, wear, and tear |

|

Water Resistance |

Water-resistant material; easy to clean and maintain |

|

Advantage |

15-20 days delivery time, pairs of service, quality control from the source |

|

Breathability |

Less breathable than genuine leather; may retain heat and moisture |

|

Eco-Friendliness |

Synthetic material alternative to genuine leather; environmentally-friendly and cruelty-free |

|

Usage |

sofa,car seat,bag,upholstery,shoe,floor,Furniture,Garment, Notebook,etc. |

|

Cost |

Less expensive than genuine leather; cost-effective alternative |

Standard Physical Properties

● Yellowing discoloring after @70℃≥ 4.0 grade

● Color change after hydrolysis ≥ 4.0 grade

● (Temperature 70°C, Humidity 90%, 72 Hours)

● Bally flexing dry : 100,000 Cycles

● Tear growth strength ≥50N

● Peeling strength ≥ 2.5KG/CM

● Color fastness to crocking ≥ 4.0 grade

● Taber H22/500G)

● Taber abrasion>200 Cycles

● Chemical resistance passed REACH, ROHS, California 65 and RSL tests of various brands