Polyurethane is an emerging organic polymer material, known as the "The Fifth Plastic", and is widely used in many fields of the national economy because of its excellent performance. At present, China is the largest producer of polyurethane in the world, accounting for about 45% of global polyurethane production. There are many kinds of polyurethane products, and polyurethane elastomer is one of them. Polyurethane elastomer is a series of elastomer materials containing more carbamate groups on the polymer main chain, and it is a polymer material that can recover well after the external force applied to it is eliminated.

Polyurethane elastomers can be divided into thermoplastic polyurethane elastomers (TPU), cast polyurethane elastomers (CPU) and mixing polyurethane elastomers (MPU) according to different processes, among which TPU is the largest. The TPU industry is a branch of the polyurethane industry, located in the downstream of the entire chemical industry chain, closer to the end consumer market.

01 Classification of polyurethane elastomers

TPU is a polyurethane elastomer product. The raw materials such as polyols, MDI, BDO, adipic acid, and ethylene glycol required for its production are all petroleum derivatives or by-products, and are downstream products of petrochemicals. TPU is a branch of thermoplastic elastomer materials. It is a polymer material polymerized from three basic raw materials: diisocyanate, macromolecular polyol, and chain extender (low molecular diol).

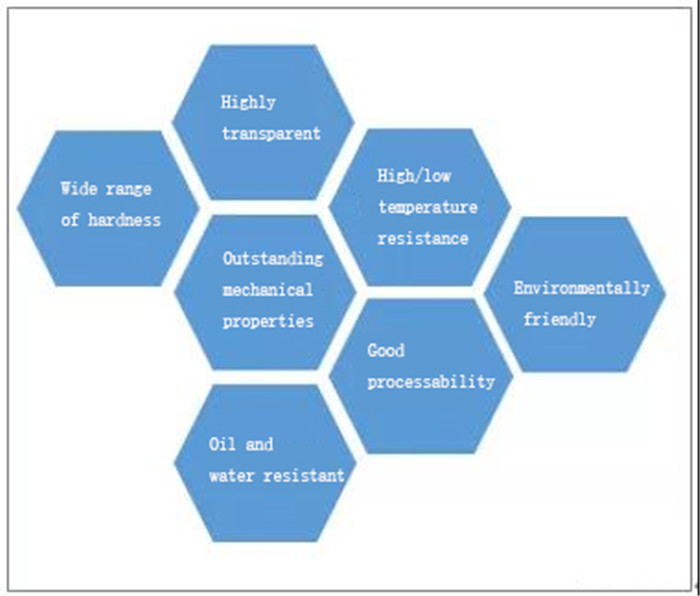

Compared with general-purpose plastic and rubber materials, TPU has a wide range of hardness, outstanding mechanical properties, excellent high/low temperature resistance, good processing performance, excellent environmental performance, strong plasticity, strong designability, and excellent transparency. It not only has the high elasticity of rubber materials, but also has the high strength of engineering plastics.

02 TPU material characteristics

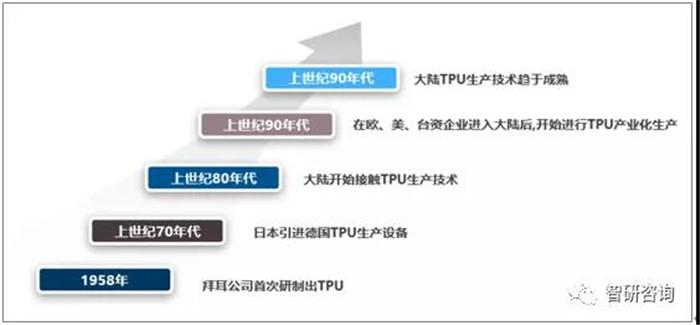

TPU was first successfully developed by Bayer in 1958, and major chemical companies in Europe and the United States successively developed and put it into production. In the 1970s, Japan introduced German TPU production equipment and introduced TPU production technology to Taiwan. Mainland China has been exposed to TPU production technology since the 1980s, but has not achieved breakthroughs in research and development and technology. After the 1990s, with the increasing market demand for TPU materials, after European, American and Taiwan-funded enterprises entered the mainland, some mainland enterprises began to produce and sell TPU.

03 Development history of global and Chinese TPU industry

Thanks to its excellent product performance, the market demand for TPU in many national economic fields such as daily consumer goods, industrial production, medical health, national defense and military industry has increased significantly. In recent years, my country's new TPU production capacity has been released one after another, and the TPU operating rate has steadily increased in 2018 and 2019. From 2014 to 2019, the compound annual growth rate of domestic TPU production is as high as 15.46%. In 2019, the scale of my country's TPU industry continued to expand, with an output of about 512,900 tons. my country has gradually surpassed Europe and the United States to become the world's largest producer and consumer of TPU, and the average annual consumption has maintained a rapid growth of about 10%.

04 Trend Chart of TPU Production in China from 2014 to 2019

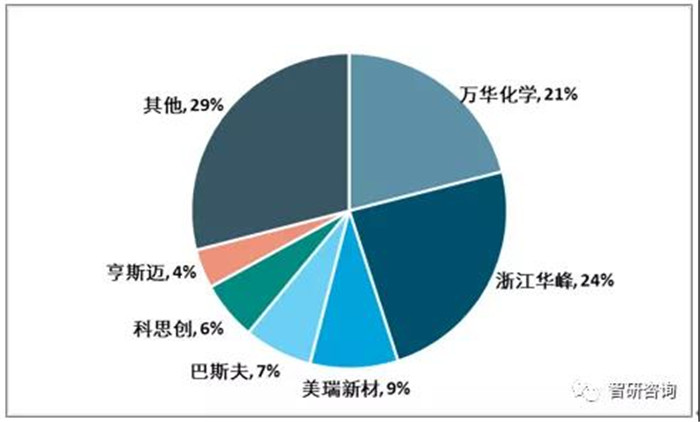

Affected by the Xiangshui incident in 2019, the government accelerated the renovation of chemical parks. At the same time, the price fluctuation of raw material isocyanate increased the production cost of some small factories. However, established manufacturers, including Huafon, BASF, and Meirui, continue to expand their lines and increase production, and accelerate their occupation of the market. The industry concentration continues to rise. Among domestic TPU suppliers, Huafon Group and Yantai Wanhua occupy the top positions in production capacity.

05 Distribution of China's TPU production pattern in 2019

Although my country's domestic TPU production scale is high, it lacks advantages in subdivided fields. Especially in the mid-to-high-end market, multinational companies such as BASF and Huntsman have outstanding technological advantages. Through efficient management models, they have improved product performance and quality while reducing product production costs, occupying a major share of the domestic mid-to-high-end and high-end markets. At present, most of the TPU manufacturers in my country are lacking in core technology advantages, single product structure, and slow progress in new products, resulting in overall weak market competitiveness, and it is difficult to effectively increase industry profits.

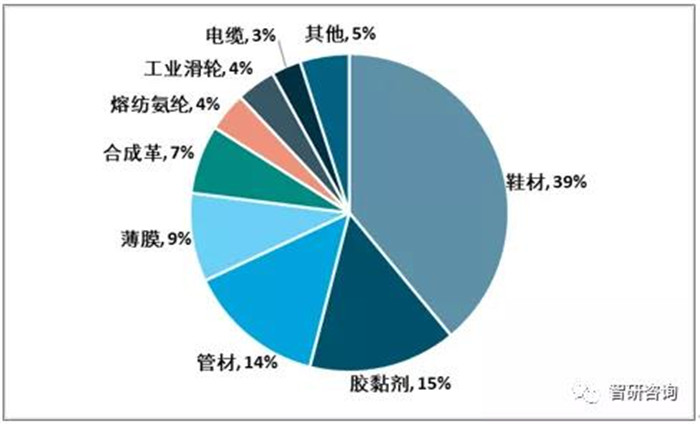

The technical development direction, scale, competition pattern, growth rate, and profit level of the TPU industry directly depend on the market demand of downstream industries.

The data shows that as traditional rubber and plastic materials are gradually replaced by environmentally friendly materials, the consumption of TPU will continue to grow, and it will be widely used in many fields of the national economy. TPU is mainly used in pipes, films, electronic appliances, shoe materials, auto parts, modified encapsulation, industrial transmission, adhesives, wires and cables and other fields. Among them, shoe materials are the main consumer market for TPU, accounting for 40% of TPU consumption.

06 China's TPU downstream application pattern

my country is the world's largest producer and exporter of footwear, and its output accounts for more than 50% of the global total. The technological innovation of sole materials is an important innovation point in the shoe industry. Compared with traditional sole materials, TPU has obvious advantages in performance, and its usage is increasing day by day. Among them, ETPU has outstanding advantages in resilience and shock absorption. The sole made of it can effectively absorb the impact of the ground and face the foot, providing high-quality cushioning effect.

On the whole, the TPU industry has the characteristics of a high proportion of raw material costs, fast product update speed, various specifications and models, and obvious differentiation of customer needs. Therefore, the profit level of the industry is affected by various factors such as fluctuations in raw material prices, new product development capabilities, and customer service levels. With the successive introduction of domestic policies and measures aimed at residents' sports health, and the improvement of residents' consumption and spending ability of sports goods, the growth of consumer demand for high-tech sports shoes will help improve the application space of the TPU industry. On the other hand, in the high-end market For varieties such as calendered TPU, medical TPU, and high-temperature-resistant TPU, the country mainly relies on imports. With the long-term technology accumulation and R&D investment of domestic TPU companies, it is expected to break through the monopoly of foreign companies and expand the domestic alternative space.

Post time: Apr-03-2023